Product Series

The production process of complete equipment and the complete equipment production chain.

Product Center

Build a systematic quality management system and an advanced quality acceptance technology platform.

About Xinyu

Create more legends in metallurgical equipment manufacturing and realize the dream of becoming a strong enterprise.

The production process of complete equipment and the complete spare parts production chain of the equipment

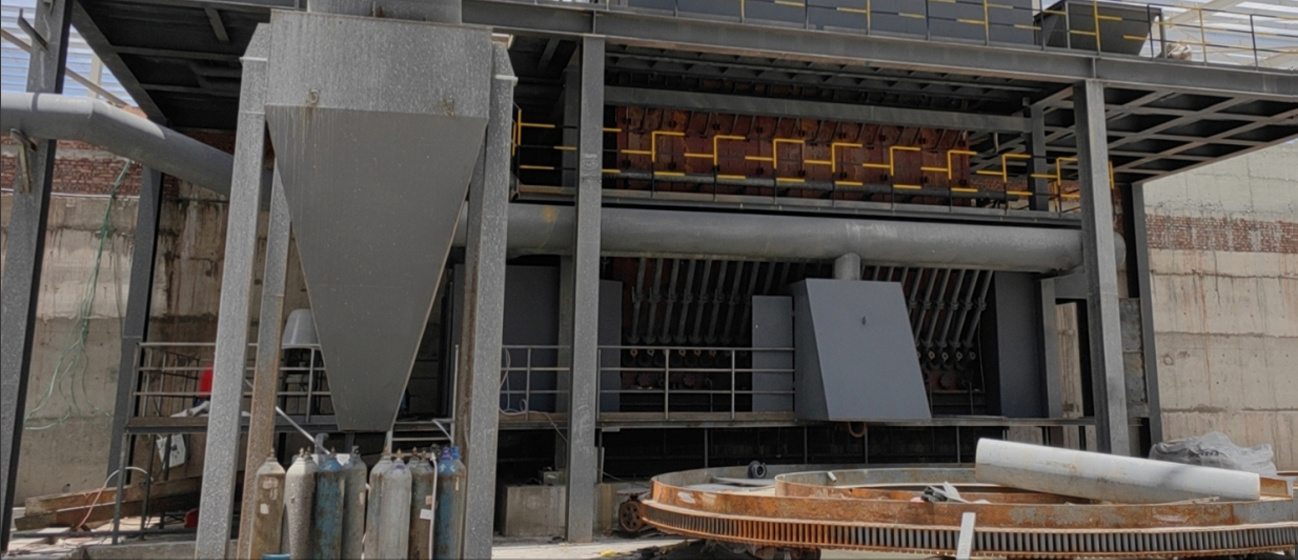

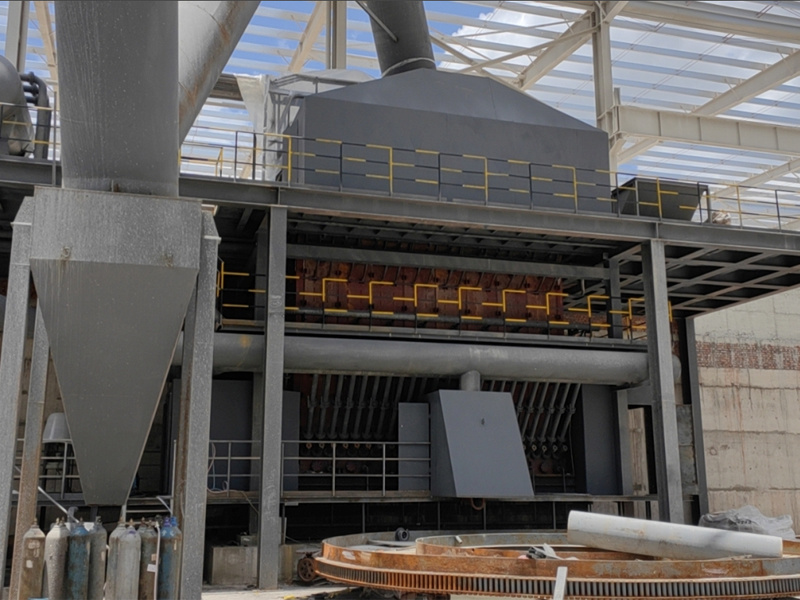

Henan Xinyu Metallurgical Equipment Co., Ltd., since its establishment, has been keeping pace with the cutting-edge technology of the lead-zinc-copper smelting industry. For many years, Henan Xinyu Metallurgical Equipment Co., Ltd., relying on advanced production technology and equipment, has continuously innovated and explored itself, and made arduous efforts to ensure the stable operation of the company's smelting system. For many years, the company has aimed at the most advanced production technology in the industry and served the most advanced production equipment, striving to consolidate the foundation for development, forming a set of equipment production processes, and a complete production chain of various equipment spare parts, such as high-quality units, lead pumps, lead pots, oxygen guns, and various accessories and various supporting environmental protection equipment, etc.

Company Founded in

Registered Capital

Cooperative Customers

Customer Satisfaction

Strong Strength

We have an internationally advanced lead smelting production system and supporting environmental protection equipment to help you achieve your dream of becoming a strong enterprise.

Complete industrial chain

We provide a complete production chain for metallurgical equipment, including high-quality units, lead pumps, lead pots, oxygen lances, and a variety of supporting environmental protection equipment tailored to diverse industry needs

Customized services

A state-of-the-art quality acceptance platform ensures that every production step undergoes rigorous testing and inspection by expert technicians, guaranteeing zero defects and flawless product performance—giving users peace of mind

After-sale service

We always answer customers' questions, provide attentive service, establish customer documents, regularly follow up on product usage, and serve every customer with care.

Win the World with Quality

Create more metallurgical equipment manufacturing legends and help you achieve your dream of becoming a strong enterprise.

Blog Center

To provide customers and the market with more high-quality products and services.

Sep 11,2025

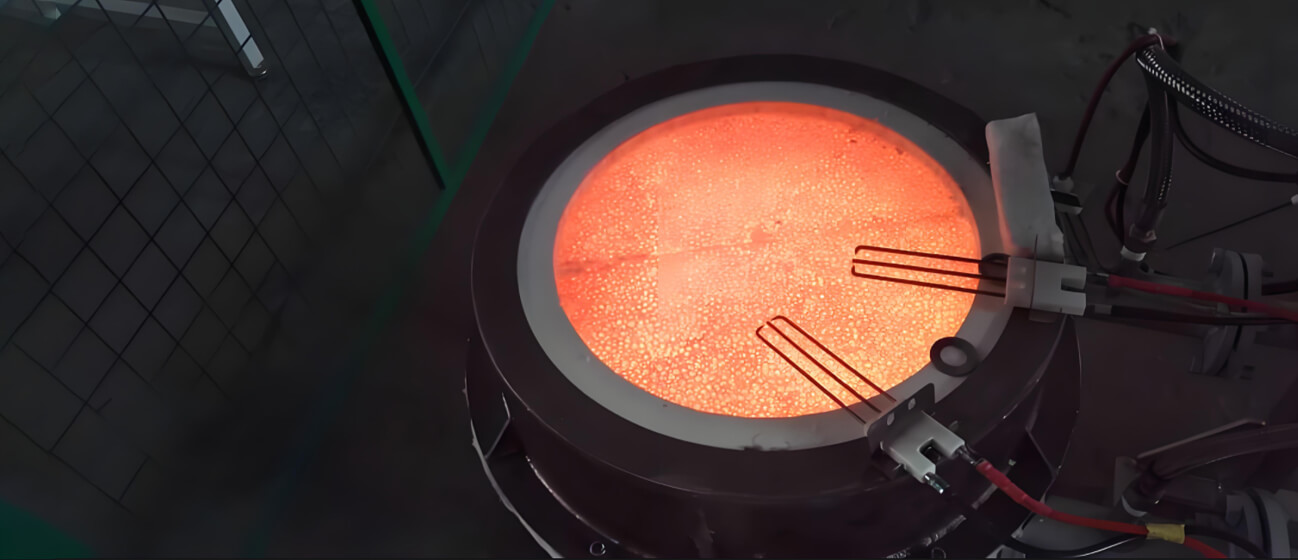

Understanding the Importance of a Quality Copper Anode Furnace in Industrial Applications

In the realm of industrial equipment, particularly in casting and heat treatment, the quality of the copper anode furnace plays a pivotal role in ensuring optimal performance and superior product outcomes. A quality copper anode furnace is designed to efficiently melt copper and shape it into anodes, which are essential for electrolysis in metal refining. The effectiveness of this process directly

Sep 11,2025

Unlocking Efficiency: The Role of Durable Secondary Copper Melting Furnaces in the Industry

In the realm of industrial equipment and components, especially within the smelting and metallurgical sectors, the choice of a secondary copper melting furnace is a critical decision. Among the various options available, durable secondary copper melting furnaces stand out due to their robust construction and efficiency in processing recycled copper. These furnaces are designed to withstand extreme

Sep 11,2025

Unlocking Efficiency: The Magic of Copper Melting Furnaces

Discover the intricacies of copper melting furnaces and how they revolutionize metalworking industries.

Sep 09,2025

The durable oxygen-enriched side-blown furnace is an advanced industrial device that has gained popularity in the casting and heat treatment sectors. This technology stands out by infusing oxygen into the combustion process, significantly enhancing the efficiency of metal melting and processing operations. By utilizing this method, manufacturers can achieve higher temperatures with less fuel consu

Online Message

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within 1 working day after receiving the message email.

Phone