Understanding Lead Alloy Melting Furnaces: Essential Insights for Industrial Applications

Jul 27,2025

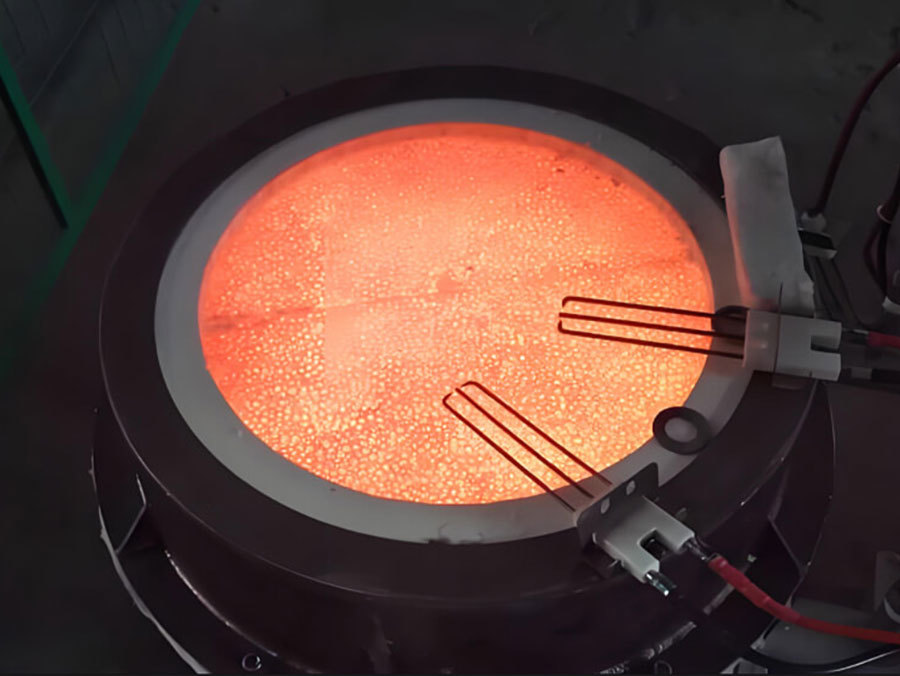

Lead Alloy Melting Furnaces are specialized industrial units designed to melt lead and its alloys. These furnaces are essential in a variety of fields, including recycling, manufacturing, and metalworking industries, where lead alloys are pivotal for producing batteries, solder, and other applications. The melting process typically involves heating the lead alloy to its melting point, which is around 327.5 degrees Celsius (621.5 degrees Fahrenheit) for pure lead.

One of the primary advantages of using a Lead Alloy Melting Furnace is its ability to achieve precise temperature control, which is vital for maintaining the integrity of the lead alloy during the melting process. This precision helps prevent oxidation and contamination, ensuring the quality of the final product. Furthermore, modern furnaces are often equipped with advanced monitoring systems that allow operators to track temperature, pressure, and other critical parameters in real-time.

Efficiency is another significant aspect of Lead Alloy Melting Furnaces. With advancements in technology, many of these furnaces are designed to optimize energy consumption, reducing operational costs while enhancing productivity. The use of insulation materials and efficient heating methods helps maintain temperature, thus minimizing energy wastage.

Safety is paramount in melting operations, especially when handling lead, which is a toxic metal. Lead Alloy Melting Furnaces are typically designed with safety features such as fume extraction systems to manage harmful emissions, ensuring a safer working environment for operators. Additionally, proper training for personnel in handling materials and emergency procedures is essential to mitigate risks associated with lead exposure.

When considering a Lead Alloy Melting Furnace, it is also important to evaluate its capacity and throughput. Different applications may require varying sizes and configurations of furnaces to meet production demands. Understanding the specific requirements of your operations will help in selecting the right furnace that aligns with your smelting needs.

In summary, Lead Alloy Melting Furnaces are a vital component of the industrial smelting landscape. Their ability to provide precise temperature control, enhance energy efficiency, and ensure safety makes them invaluable for industries working with lead alloys. As technology continues to evolve, these furnaces will likely incorporate even more advanced features, further improving their performance and safety standards. For those involved in the smelting of lead alloys, understanding the capabilities and benefits of these furnaces is key to optimizing production and maintaining high-quality output.

One of the primary advantages of using a Lead Alloy Melting Furnace is its ability to achieve precise temperature control, which is vital for maintaining the integrity of the lead alloy during the melting process. This precision helps prevent oxidation and contamination, ensuring the quality of the final product. Furthermore, modern furnaces are often equipped with advanced monitoring systems that allow operators to track temperature, pressure, and other critical parameters in real-time.

Efficiency is another significant aspect of Lead Alloy Melting Furnaces. With advancements in technology, many of these furnaces are designed to optimize energy consumption, reducing operational costs while enhancing productivity. The use of insulation materials and efficient heating methods helps maintain temperature, thus minimizing energy wastage.

Safety is paramount in melting operations, especially when handling lead, which is a toxic metal. Lead Alloy Melting Furnaces are typically designed with safety features such as fume extraction systems to manage harmful emissions, ensuring a safer working environment for operators. Additionally, proper training for personnel in handling materials and emergency procedures is essential to mitigate risks associated with lead exposure.

When considering a Lead Alloy Melting Furnace, it is also important to evaluate its capacity and throughput. Different applications may require varying sizes and configurations of furnaces to meet production demands. Understanding the specific requirements of your operations will help in selecting the right furnace that aligns with your smelting needs.

In summary, Lead Alloy Melting Furnaces are a vital component of the industrial smelting landscape. Their ability to provide precise temperature control, enhance energy efficiency, and ensure safety makes them invaluable for industries working with lead alloys. As technology continues to evolve, these furnaces will likely incorporate even more advanced features, further improving their performance and safety standards. For those involved in the smelting of lead alloys, understanding the capabilities and benefits of these furnaces is key to optimizing production and maintaining high-quality output.

TAG:

Previous:

Contact Us

Company Email:

962452762@qq.com

Contact Number:

+8615670922562

Company Address:

No. 11 Plant, Tiantan Industrial Park, Huling Industrial Cluster, Jiyuan City