Unlocking Efficiency: The Crucial Role of a Secondary Copper Melting Furnace in Recycling

Jul 26,2025

Unlocking Efficiency: The Crucial Role of a Secondary Copper Melting Furnace in Recycling

Table of Contents

- 1. Introduction to Secondary Copper Melting Furnaces

- 2. The Importance of Copper Recycling

- 3. Understanding Secondary Copper Melting Furnace Technology

- 4. Benefits of Using a Secondary Copper Melting Furnace

- 5. The Copper Recycling Process: From Scrap to Melting

- 6. Environmental Impact and Sustainability

- 7. Challenges in Copper Recycling

- 8. The Future of Secondary Copper Melting Furnaces

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Secondary Copper Melting Furnaces

In the realm of metal recycling, **secondary copper melting furnaces** play a pivotal role. These specialized furnaces are designed specifically for the efficient melting of scrap copper, facilitating the reclamation of valuable metal from discarded materials. As industries strive for sustainability and efficiency, understanding the operation and benefits of these furnaces becomes increasingly essential.

2. The Importance of Copper Recycling

Copper is one of the most widely used metals in various industries, including electrical, construction, and transportation. The **recycling of copper** not only conserves natural resources but also significantly reduces energy consumption compared to primary copper production. By recycling copper, we can help mitigate the environmental impact associated with mining and processing new copper.

The Economic Benefits of Copper Recycling

Recycling copper not only saves energy but also offers considerable economic advantages. The price of recycled copper is generally lower than that of newly mined copper, which can lead to reduced costs for manufacturers. Additionally, recycling creates jobs in local communities and supports a circular economy.

3. Understanding Secondary Copper Melting Furnace Technology

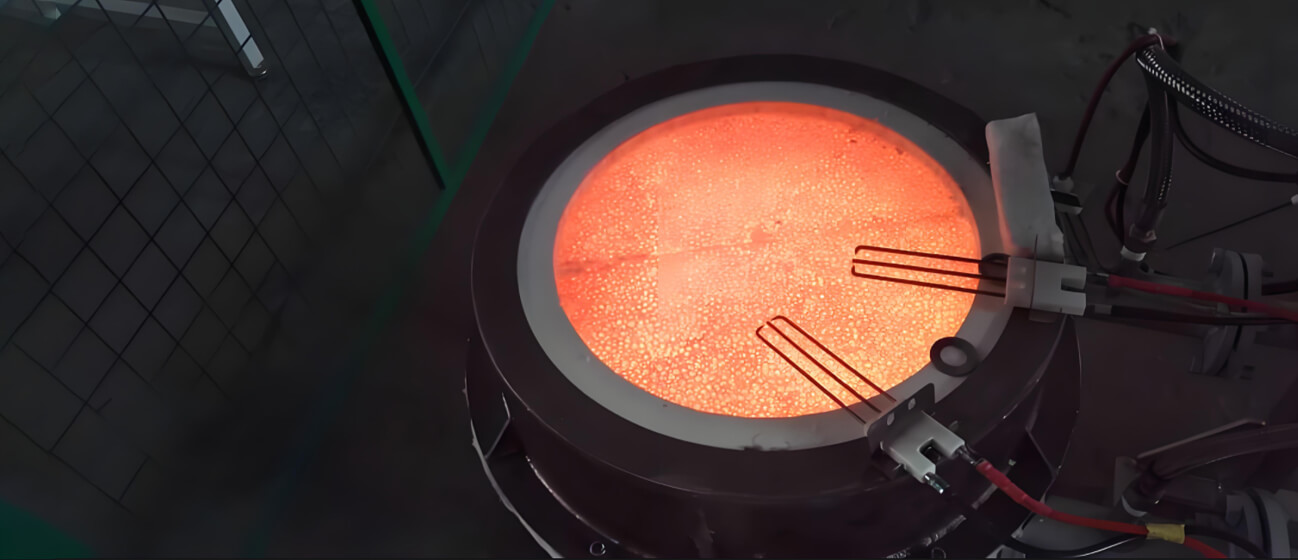

Secondary copper melting furnaces are engineered with advanced technology to enhance efficiency and reduce emissions. These furnaces typically utilize **induction heating**, electric arc, or crucible methods to melt copper scrap quickly and effectively.

The Mechanics of Induction Melting

Induction melting is a popular method in secondary copper melting furnaces, utilizing electromagnetic fields to generate heat. This method provides precise temperature control, reduces energy consumption, and minimizes oxidation during the melting process, ensuring high-quality molten copper.

Electric Arc Furnaces

Electric arc furnaces are another technology used in copper recycling, where electrical arcs are generated between electrodes to produce high temperatures. This method is effective for melting larger quantities of scrap metal and allows for the efficient recovery of impurities.

4. Benefits of Using a Secondary Copper Melting Furnace

The use of a secondary copper melting furnace presents numerous advantages for recycling operations:

Enhanced Efficiency

These furnaces are designed for rapid melting, allowing operators to process large volumes of scrap copper in shorter periods. The efficiency of these systems translates into lower operational costs and increased productivity.

Improved Metal Quality

Secondary melting furnaces produce high-quality copper with minimal impurities. The controlled environments in these furnaces reduce oxidation and contamination, resulting in a superior end product that meets industry standards.

Cost-Effectiveness

By utilizing secondary copper melting furnaces, recyclers can significantly cut down on their energy consumption and operational costs. The savings are further compounded by the reduced need for raw material extraction and processing.

5. The Copper Recycling Process: From Scrap to Melting

The journey of scrap copper to recycled material involves several critical stages:

Collection and Sorting

The first step in the copper recycling process is the collection of scrap copper from various sources, including construction sites, electrical waste, and manufacturing facilities. Once collected, the copper is sorted to separate it from other materials.

Shredding and Preparation

After sorting, the copper scrap is shredded into smaller pieces to facilitate melting. This preparation step ensures that the material can be evenly melted, improving the overall efficiency of the process.

Melting and Refining

Once prepared, the copper scrap is loaded into the secondary melting furnace. The melting process involves heating the scrap to a temperature above its melting point, allowing it to flow and be cast into new shapes. During this phase, impurities are removed through refining processes, ensuring high-quality output.

6. Environmental Impact and Sustainability

The environmental benefits of copper recycling are significant. By utilizing a secondary melting furnace, recyclers can reduce their carbon footprint and energy consumption. Compared to primary copper production, recycling consumes up to 85% less energy, resulting in reduced greenhouse gas emissions.

Promoting a Circular Economy

Investing in secondary copper melting technology supports a circular economy by encouraging the reuse and recycling of materials. This approach not only conserves resources but also fosters sustainable practices within the industry.

7. Challenges in Copper Recycling

Despite the numerous benefits, the recycling industry faces several challenges:

Quality Control

Maintaining consistent quality in recycled copper can be difficult due to contamination with other metals and materials during collection and sorting. Advanced technologies and strict quality control measures are essential to address this issue.

Market Fluctuations

The copper recycling market is susceptible to price fluctuations, which can impact profitability. Recyclers must adapt to changing market conditions to remain competitive.

8. The Future of Secondary Copper Melting Furnaces

As technology continues to evolve, the future of secondary copper melting furnaces looks promising. Innovations in furnace design, automation, and efficiency are paving the way for enhanced recycling capabilities.

Integration of Smart Technologies

The incorporation of smart technologies, such as IoT (Internet of Things) sensors and AI (Artificial Intelligence), is poised to revolutionize the recycling process. These advancements will enable real-time monitoring, predictive maintenance, and further optimization of melting processes.

9. Frequently Asked Questions

1. What is a secondary copper melting furnace?

A secondary copper melting furnace is a specialized piece of equipment used to melt recycled copper scrap, enabling efficient metal recovery and purity enhancement.

2. How does copper recycling benefit the environment?

Copper recycling conserves energy, reduces greenhouse gas emissions, and minimizes pollution compared to primary copper production, thus benefiting the environment.

3. What technologies are used in secondary copper melting furnaces?

Common technologies include induction melting and electric arc furnaces, both of which efficiently melt copper scrap.

4. Why is quality control important in copper recycling?

Maintaining high-quality standards is crucial to ensure the recycled copper meets industry specifications and is free from impurities.

5. What challenges does the copper recycling industry face?

Challenges include quality control, market fluctuations, and the need for advanced technology to optimize processes.

10. Conclusion

In conclusion, secondary copper melting furnaces are vital to the recycling industry, offering enhanced efficiency, improved metal quality, and significant environmental benefits. As we advance towards a more sustainable future, the role of these furnaces will become increasingly important in maximizing the potential of recycled copper. Embracing technology and innovation will not only improve recycling processes but also contribute to a greener, more sustainable world.

TAG:

Previous:

Contact Us

Company Email:

962452762@qq.com

Contact Number:

+8615670922562

Company Address:

No. 11 Plant, Tiantan Industrial Park, Huling Industrial Cluster, Jiyuan City