Intelligent production becomes the highlight!

Mar 28,2025

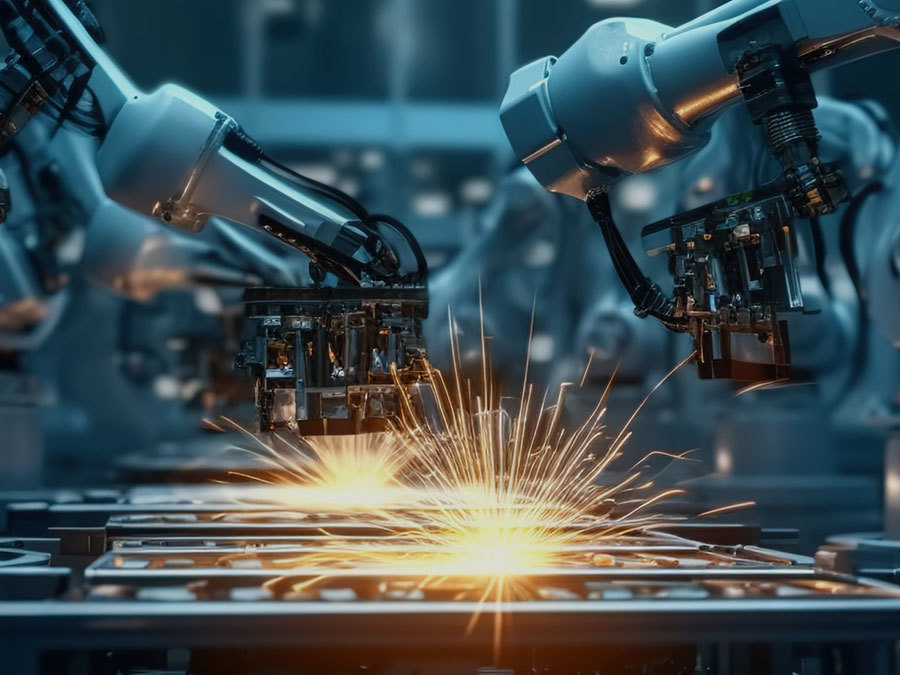

At the 2023 International Metallurgical Equipment Exhibition, a global event, a heavy industry group, relying on its strength and innovation, grandly launched the world's first intelligent primary copper refining unit. This breakthrough quickly attracted widespread attention and heated discussions inside and outside the industry. This unit not only represents the forefront of current metallurgical technology, but also a revolutionary exploration of the future copper refining production model.

The core competitiveness of this intelligent primary copper refining unit lies in its advanced AI algorithm control system. Through precise algorithms, the system can control the injection angle of the oxygen gun and the temperature of the molten pool in real time to ensure that every link in the refining process is in good condition. At the same time, the unit is also equipped with a high corrosion-resistant lead pump independently developed by the heavy industry group. This innovative design further improves the refining efficiency of crude copper. According to statistics, compared with traditional processes, the refining efficiency has increased by 40%, which undoubtedly brings a qualitative leap in the company's production efficiency and cost control.

However, the highlights of this unit are far more than that. Its supporting waste heat recovery device gives full play to the concept of energy saving and environmental protection. This device can effectively convert waste heat generated during the refining process into electrical energy, which not only realizes the recycling of resources, but also saves a lot of energy costs for enterprises. According to preliminary estimates, the waste heat recovery device can save enterprises more than 5 million yuan in costs each year, which is undoubtedly of far-reaching significance for improving the comprehensive competitiveness of enterprises.

At the exhibition site, the Heavy Industry Group also simultaneously displayed more than 200 spare parts including ingot casting machines, copper ladle, etc., as well as a new "full life cycle service system". With the help of the Internet of Things platform, this system provides customers with a one-stop solution for equipment early warning and direct purchase of spare parts. Customers only need to use the Internet of Things platform to understand the operating status of the equipment in real time, obtain early warning information in time, and directly purchase spare parts when needed, which greatly improves the maintenance efficiency and reliability of the equipment.

Industry experts have given high praise to this, believing that this technical system launched by the Heavy Industry Group will not only accelerate the pace of the copper smelting industry's transformation to digitalization and low carbonization, but will also lead the entire metallurgical industry towards a more efficient, environmentally friendly and sustainable development path. This innovative achievement has undoubtedly set a new benchmark for the future metallurgical equipment industry and injected new vitality and hope into the transformation and upgrading of the global copper smelting industry.

Contact Us

Company Email:

962452762@qq.com

Contact Number:

+8615670922562

Company Address:

No. 11 Plant, Tiantan Industrial Park, Huling Industrial Cluster, Jiyuan City