Sustainability in Metal Processing: Advanced Copper Melting Furnaces Lead the Way

Sep 08,2025

Sustainability in Metal Processing: Advanced Copper Melting Furnaces Lead the Way

Table of Contents

- 1. Introduction to Sustainability in Metal Processing

- 2. The Role of Advanced Copper Melting Furnaces

- 3. Advancements in Copper Melting Technologies

- 4. Environmental Impact of Copper Production

- 5. Energy Efficiency in Metal Processing

- 6. Recycling and Resource Recovery

- 7. Best Practices for Sustainable Metal Processing

- 8. Future of Sustainability in Metal Processing

- 9. Frequently Asked Questions (FAQs)

- 10. Conclusion

1. Introduction to Sustainability in Metal Processing

In today’s industrial landscape, **sustainability** has emerged as a crucial pillar that drives innovation and efficiency. As we navigate an era marked by climate change and resource scarcity, the need for sustainable practices in the metal processing industry is more critical than ever. Advanced **copper melting furnaces** are at the forefront of this transformation, offering technologies that not only enhance productivity but also significantly minimize environmental impacts.

Sustainability in metal processing involves various strategies and technologies aimed at reducing waste, conserving energy, and optimizing material usage while maintaining high productivity levels. In this article, we will explore how advanced copper melting furnaces are leading the way toward a greener future in metal processing.

2. The Role of Advanced Copper Melting Furnaces

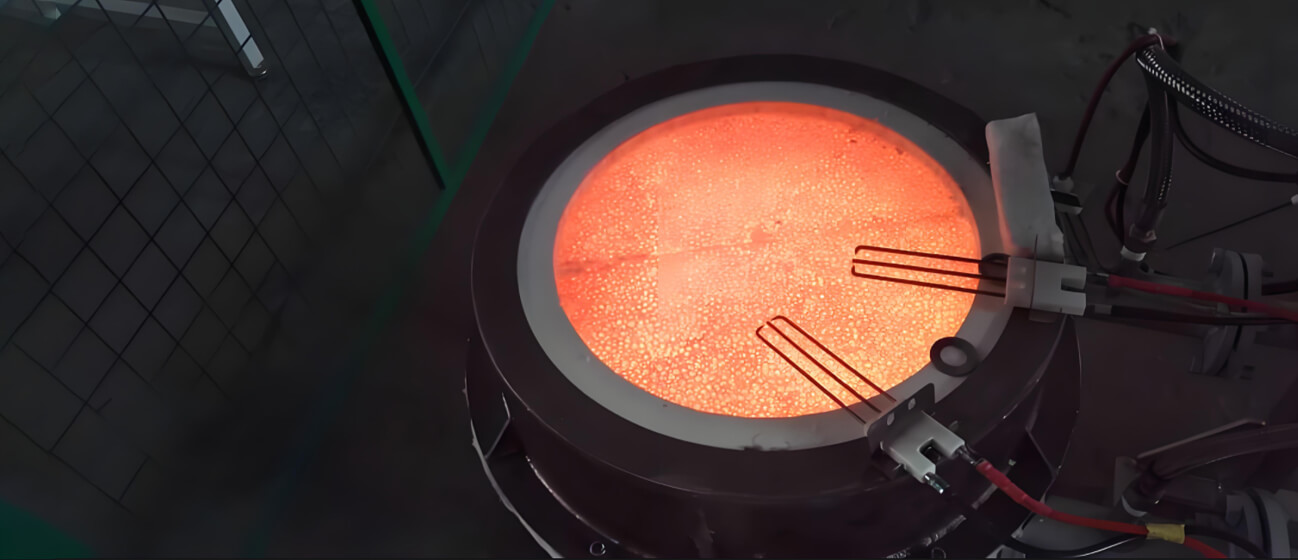

**Copper melting furnaces** play a vital role in the metal processing industry. These furnaces are designed to melt copper and its alloys, facilitating the production of high-quality metal products. The efficiency and technology embedded in modern melting furnaces directly impact the sustainability of metal processing operations.

Advanced copper melting furnaces utilize new technologies that enhance thermal efficiency, reduce emissions, and lower energy consumption. By implementing these innovations, manufacturers can produce copper more sustainably while adhering to stringent environmental regulations.

2.1 Types of Copper Melting Furnaces

There are several types of copper melting furnaces, each serving different purposes and industries:

- **Induction Furnaces**: These furnaces use electromagnetic induction to heat and melt copper efficiently. They are known for their energy efficiency and minimal emissions.

- **Arc Furnaces**: Employing electric arcs to generate heat, arc furnaces are popular in large-scale copper production due to their high melting capacity.

- **Crucible Furnaces**: Ideal for small-scale operations, crucible furnaces provide a simple and effective way to melt copper and are often used for specialty applications.

Each furnace type has its advantages, but the continuous development of **induction technology** stands out for its sustainability benefits.

2.2 Benefits of Advanced Copper Melting Furnaces

The benefits of advanced copper melting furnaces extend beyond mere productivity. Key advantages include:

- **Reduced Energy Consumption**: Modern furnaces are designed to operate with lower energy inputs, which translates to reduced electricity costs and less environmental impact.

- **Lower Emissions**: Advanced furnaces significantly minimize harmful emissions, aligning with global efforts to combat climate change.

- **Higher Recovery Rates**: Innovations in furnace design lead to improved material recovery rates, ensuring that more metal can be repurposed and reused.

3. Advancements in Copper Melting Technologies

The evolution of copper melting technologies is pivotal for achieving sustainability in metal processing. Innovations focus on enhancing **efficiency** and **reducing waste**, which are essential factors for environmentally responsible production.

3.1 Smart Furnace Technologies

Smart technologies integrated into copper melting furnaces allow for real-time monitoring and control of operations. These systems can:

- Optimize melting processes based on material characteristics.

- Provide data analytics to track performance and identify inefficiencies.

- Enable predictive maintenance, leading to reduced downtime and improved reliability.

By leveraging smart technologies, manufacturers can achieve a higher level of operational efficiency.

3.2 Use of Alternative Fuels

To further enhance sustainability, many facilities are exploring the use of alternative fuels in conjunction with traditional energy sources. This shift can reduce reliance on fossil fuels and minimize carbon footprints. Some options include:

- **Biomass**: Utilizing organic materials as a fuel source offers a renewable alternative.

- **Electrification**: Transitioning to electric melting processes powered by renewable energy sources can dramatically reduce greenhouse gas emissions.

4. Environmental Impact of Copper Production

While copper is essential for various applications, its production historically comes with significant environmental costs. Understanding these impacts is crucial for developing strategies to mitigate them.

4.1 Resource Depletion

Copper mining and processing consume vast amounts of natural resources, leading to habitat destruction and biodiversity loss. By improving melting technologies and adopting recycling practices, these impacts can be substantially reduced.

4.2 Water Usage and Pollution

The copper production process requires considerable water use, which can lead to resource depletion in many regions. Additionally, runoff from mining sites can contaminate local water supplies.

Implementing closed-loop water systems and advanced filtration technologies can greatly reduce water usage and prevent contamination.

4.3 Carbon Emissions

The metal processing industry is a significant contributor to global carbon emissions. Advanced copper melting furnaces that utilize cleaner technologies can help minimize these emissions, aligning with global climate goals.

5. Energy Efficiency in Metal Processing

Energy efficiency is a cornerstone of sustainability in metal processing. Advanced copper melting furnaces are engineered for optimal energy use, directly impacting production costs and environmental sustainability.

5.1 Heat Recovery Systems

Many modern furnaces incorporate heat recovery systems that capture excess heat generated during the melting process. This reclaimed energy can be repurposed for other operational needs, reducing overall energy consumption.

5.2 Automation and Control Systems

Integrating automation and advanced control systems can enhance the efficiency of copper melting processes. By optimizing heating cycles and reducing idle times, manufacturers can achieve significant energy savings.

6. Recycling and Resource Recovery

Recycling is an essential component of sustainable metal processing, particularly for copper. The metal can be recycled numerous times without losing its properties, making it a highly sustainable material.

6.1 Importance of Copper Recycling

Recycling copper reduces the need for virgin material extraction, which in turn lessens the environmental impacts associated with mining. Advanced copper melting furnaces can efficiently process recycled copper, contributing to a circular economy.

6.2 Techniques for Effective Recycling

To optimize recycling efforts, facilities can implement:

- **Separation Technologies**: These technologies help isolate copper from other materials, enhancing recovery rates.

- **Advanced Sorting Systems**: Utilizing AI and machine learning can improve sorting accuracy, leading to higher quality recycled copper.

7. Best Practices for Sustainable Metal Processing

Implementing best practices in metal processing is essential for achieving sustainability goals. Here are several key strategies:

7.1 Conducting Sustainability Audits

Regular sustainability audits can help identify areas for improvement in production processes, energy use, and waste management. This proactive approach fosters continuous improvement.

7.2 Employee Training and Engagement

Investing in employee training programs ensures that workers are aware of sustainable practices and technologies. Engaged employees are more likely to contribute to the company's sustainability initiatives.

7.3 Collaborating with Supply Chains

Building partnerships with suppliers who prioritize sustainability can enhance the overall environmental performance of metal processing operations. Collaborating on sustainable practices across the supply chain is essential for maximizing impact.

8. Future of Sustainability in Metal Processing

The future of sustainability in metal processing looks promising, driven by continuous innovation and a commitment to environmental stewardship. Key trends include:

8.1 Increased Regulatory Pressures

As global awareness of environmental issues grows, regulatory bodies are implementing stricter guidelines for metal processing. Companies that adapt quickly will be better positioned for success in a changing landscape.

8.2 Technological Innovations

Advancements in technology, such as AI, machine learning, and IoT, will continue to drive sustainability efforts in the metal processing sector. These technologies will enhance efficiency, reduce waste, and lower emissions.

8.3 Emphasis on Circular Economy

The shift towards a circular economy will play a significant role in shaping the future of metal processing. Companies will increasingly focus on recycling, resource recovery, and sustainable sourcing.

9. Frequently Asked Questions (FAQs)

9.1 What are the main benefits of advanced copper melting furnaces?

The primary benefits include reduced energy consumption, lower emissions, improved recovery rates, and enhanced operational efficiency.

9.2 How does copper recycling contribute to sustainability?

Copper recycling reduces the need for mining raw materials, minimizes waste, and lowers environmental impacts associated with the production process.

9.3 What technologies are being used to improve energy efficiency in metal processing?

Technologies like heat recovery systems, smart automation, and advanced control systems are being utilized to enhance energy efficiency in metal processing.

9.4 Why is sustainability important in the metal processing industry?

Sustainability is critical for minimizing environmental impacts, reducing resource depletion, and meeting regulatory requirements while ensuring long-term industry viability.

9.5 What role do regulatory pressures play in promoting sustainability?

Regulatory pressures encourage companies to adopt environmentally friendly practices and technologies, ensuring compliance and fostering a more sustainable industrial landscape.

10. Conclusion

Advanced copper melting furnaces are leading the charge toward a more sustainable future in metal processing. By embracing innovative technologies and practices, the industry can significantly reduce its environmental footprint while maintaining productivity and profitability. As we look ahead, the commitment to sustainability will not only benefit the planet but also position companies at the forefront of a rapidly evolving market. Embracing these changes will be essential for securing a sustainable and prosperous future in the metal processing industry.

TAG:

Contact Us

Company Email:

962452762@qq.com

Contact Number:

+8615670922562

Company Address:

No. 11 Plant, Tiantan Industrial Park, Huling Industrial Cluster, Jiyuan City