The Ultimate Guide to Metal Refining Equipment: Enhancing Efficiency and Purity

Sep 05,2025

Metal refining is a crucial process in various industrial operations, aimed at extracting pure metals from ores and recycling scrap metal. The efficiency and effectiveness of this process largely depend on the quality of the metal refining equipment used. Understanding the best metal refining equipment available can help industrial operators enhance their productivity and ensure superior results.

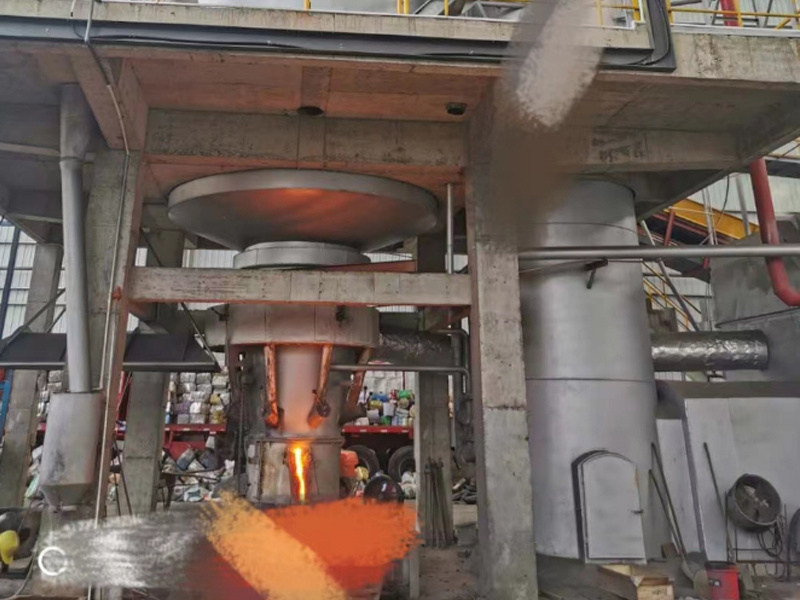

At the heart of metal refining are several types of equipment designed for different stages of the process. These may include furnaces, electrolysis cells, and refining towers. Each type serves a specific purpose: furnaces are used for melting and purifying metals at high temperatures, while electrolysis offers a method for separating metals from their ores through electrical processes. Refining towers, on the other hand, provide a way to distill metals to remove impurities.

When selecting the best metal refining equipment, operators should consider several factors, such as the type of metal being processed, the scale of operations, and the desired level of purity. For instance, some processes may require high-temperature furnaces for smelting, while others may benefit from advanced electrorefining methods that maximize recovery rates and minimize energy consumption.

Another important consideration is the technology integrated into the equipment. Modern advancements, such as automation and data analytics, can greatly enhance the efficiency of refining operations. Automated systems can optimize processes by adjusting parameters in real-time, leading to better consistency and lower operational costs. Additionally, monitoring systems can provide valuable insights into performance, allowing for proactive maintenance and reduced downtime.

Moreover, operators should also pay attention to the environmental impact of their metal refining processes. Selecting equipment that incorporates energy-efficient technologies and minimizes waste can not only comply with regulations but also enhance the company’s sustainability profile. Investing in eco-friendly refining solutions demonstrates a commitment to responsible manufacturing practices.

Finally, proper training and maintenance of refining equipment are essential for ensuring optimal performance. Staff should be well-versed in operating various types of equipment, and regular maintenance schedules should be established to prevent malfunctions and extend the lifespan of the machinery.

In conclusion, understanding the best metal refining equipment is vital for anyone involved in the industrial sector. By carefully selecting the right tools and employing best practices, companies can achieve efficient processing, higher purity levels, and a reduced environmental footprint. This knowledge empowers operators to make informed decisions that lead to successful metal refining operations.

At the heart of metal refining are several types of equipment designed for different stages of the process. These may include furnaces, electrolysis cells, and refining towers. Each type serves a specific purpose: furnaces are used for melting and purifying metals at high temperatures, while electrolysis offers a method for separating metals from their ores through electrical processes. Refining towers, on the other hand, provide a way to distill metals to remove impurities.

When selecting the best metal refining equipment, operators should consider several factors, such as the type of metal being processed, the scale of operations, and the desired level of purity. For instance, some processes may require high-temperature furnaces for smelting, while others may benefit from advanced electrorefining methods that maximize recovery rates and minimize energy consumption.

Another important consideration is the technology integrated into the equipment. Modern advancements, such as automation and data analytics, can greatly enhance the efficiency of refining operations. Automated systems can optimize processes by adjusting parameters in real-time, leading to better consistency and lower operational costs. Additionally, monitoring systems can provide valuable insights into performance, allowing for proactive maintenance and reduced downtime.

Moreover, operators should also pay attention to the environmental impact of their metal refining processes. Selecting equipment that incorporates energy-efficient technologies and minimizes waste can not only comply with regulations but also enhance the company’s sustainability profile. Investing in eco-friendly refining solutions demonstrates a commitment to responsible manufacturing practices.

Finally, proper training and maintenance of refining equipment are essential for ensuring optimal performance. Staff should be well-versed in operating various types of equipment, and regular maintenance schedules should be established to prevent malfunctions and extend the lifespan of the machinery.

In conclusion, understanding the best metal refining equipment is vital for anyone involved in the industrial sector. By carefully selecting the right tools and employing best practices, companies can achieve efficient processing, higher purity levels, and a reduced environmental footprint. This knowledge empowers operators to make informed decisions that lead to successful metal refining operations.

TAG:

Contact Us

Company Email:

962452762@qq.com

Contact Number:

+8615670922562

Company Address:

No. 11 Plant, Tiantan Industrial Park, Huling Industrial Cluster, Jiyuan City