Understanding Metallurgical Equipment: The Backbone of Smelting Operations

Jul 29,2025

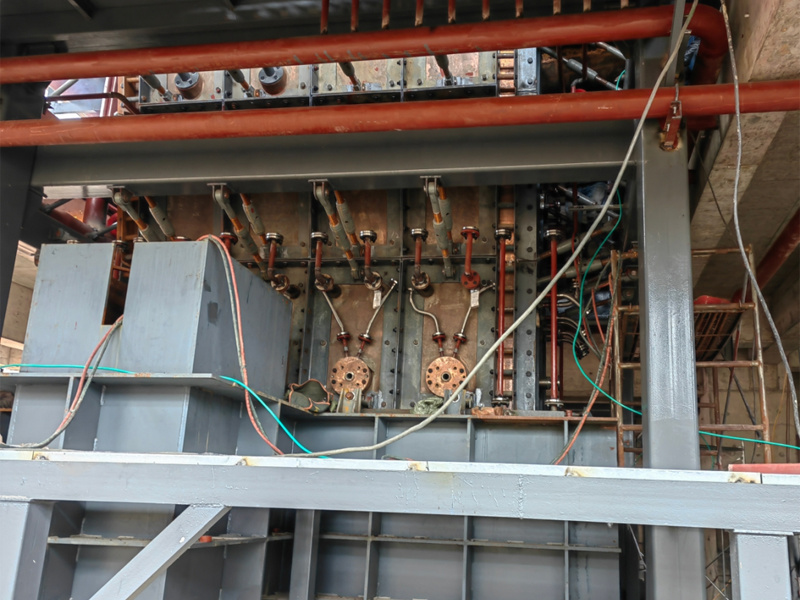

Metallurgical equipment plays a crucial role in the smelting and metal production industry, serving as the backbone for various processes involved in extracting metals from their ores. This specialized equipment is designed to operate under extreme conditions, ensuring the successful transformation of raw materials into valuable metal products. Understanding the different types of metallurgical equipment is essential for anyone involved in or interested in the industrial equipment and components sector.

At the heart of metallurgical operations are furnaces, which come in various forms such as blast furnaces, electric arc furnaces, and induction furnaces. Each type serves a specific purpose, depending on the metal being extracted and the desired production efficiency. For instance, blast furnaces are primarily used for iron production, where they combine iron ore, coke, and limestone at high temperatures to produce molten iron. Electric arc furnaces, on the other hand, are favored for recycling scrap metal due to their flexibility and lower energy consumption. Understanding these differences helps in selecting the appropriate equipment for particular smelting processes.

Beyond furnaces, other metallurgical equipment includes converters, which are used to refine molten metal by removing impurities, and ladles, which transport and pour the molten metal during casting. Auxiliary equipment like cooling systems, material handling tools, and dust collection systems are also vital for maintaining efficiency and safety in smelting operations. Each piece of equipment must work seamlessly together to ensure optimal performance and minimize downtime.

Efficiency and sustainability are increasingly important in the metallurgical sector. Advanced metallurgical equipment is now being designed with energy-saving features and reduced environmental impact in mind. Innovations such as automation and digital monitoring systems are enhancing operational efficiency, reducing waste, and improving safety for workers in smelting facilities. As the industry evolves, staying updated on the latest technologies in metallurgical equipment is essential for companies aiming to remain competitive.

Ultimately, understanding metallurgical equipment is vital for anyone involved in the smelting and metal production industry. With the right equipment, companies can enhance their production processes, ensure high-quality metal outputs, and contribute to a more sustainable future in metal manufacturing. Whether you're a professional in the field or a stakeholder exploring the industrial equipment landscape, grasping the intricacies of metallurgical equipment will provide valuable insights into the heart of metal production.

At the heart of metallurgical operations are furnaces, which come in various forms such as blast furnaces, electric arc furnaces, and induction furnaces. Each type serves a specific purpose, depending on the metal being extracted and the desired production efficiency. For instance, blast furnaces are primarily used for iron production, where they combine iron ore, coke, and limestone at high temperatures to produce molten iron. Electric arc furnaces, on the other hand, are favored for recycling scrap metal due to their flexibility and lower energy consumption. Understanding these differences helps in selecting the appropriate equipment for particular smelting processes.

Beyond furnaces, other metallurgical equipment includes converters, which are used to refine molten metal by removing impurities, and ladles, which transport and pour the molten metal during casting. Auxiliary equipment like cooling systems, material handling tools, and dust collection systems are also vital for maintaining efficiency and safety in smelting operations. Each piece of equipment must work seamlessly together to ensure optimal performance and minimize downtime.

Efficiency and sustainability are increasingly important in the metallurgical sector. Advanced metallurgical equipment is now being designed with energy-saving features and reduced environmental impact in mind. Innovations such as automation and digital monitoring systems are enhancing operational efficiency, reducing waste, and improving safety for workers in smelting facilities. As the industry evolves, staying updated on the latest technologies in metallurgical equipment is essential for companies aiming to remain competitive.

Ultimately, understanding metallurgical equipment is vital for anyone involved in the smelting and metal production industry. With the right equipment, companies can enhance their production processes, ensure high-quality metal outputs, and contribute to a more sustainable future in metal manufacturing. Whether you're a professional in the field or a stakeholder exploring the industrial equipment landscape, grasping the intricacies of metallurgical equipment will provide valuable insights into the heart of metal production.

TAG:

Previous:

Contact Us

Company Email:

962452762@qq.com

Contact Number:

+8615670922562

Company Address:

No. 11 Plant, Tiantan Industrial Park, Huling Industrial Cluster, Jiyuan City